From Marfa Public Radio:

In parts of Texas, the prickly pear cactus is everywhere — potted outside coffee shops, dotting the side of the road, poking out of cracks in the sidewalk. It also lines the pathways of the University of Texas at El Paso campus, including the path where Navid Attarzadeh, a materials engineer, has made the trek to his office for years. And every day on his walk he’d pass a prickly pear cactus, come rain, come shine, or a lot of shine. On the day I caught up with Attarzadeh, the temperature topped out at 110 degrees.

It was intense desert heat like this that got Attarzadeh thinking. As the seasons changed, he noticed that even in the face of blistering heat and blustery winds, the prickly pear fruit didn’t budge or dry out, due to the plant’s unique structure. “Usually fruits are connected to branches,” he said, “but here we have the fruit connected to leaves. And that is amazing.”

This gave Attarzadeh an idea, which he brought back to his adviser at the Center for Advanced Materials Research, Ramana Chintalapalle. Attarzadeh works in the materials processing lab, a space dedicated to finding alternative substances to use in chemical reactions and technology development.

“Those materials must be economically viable and should be more environmental friendly, as well as giving best performance that [they] could,” Chintalapalle said.

One focus of the lab is electrolysis: the process that splits water molecules into hydrogen and oxygen. Hydrogen gas can be used as an alternative to fossil fuels for producing energy. But it’s a costly process. “Right now,” Chintalapalle said, “everything is dependent on expensive materials such as platinum.”

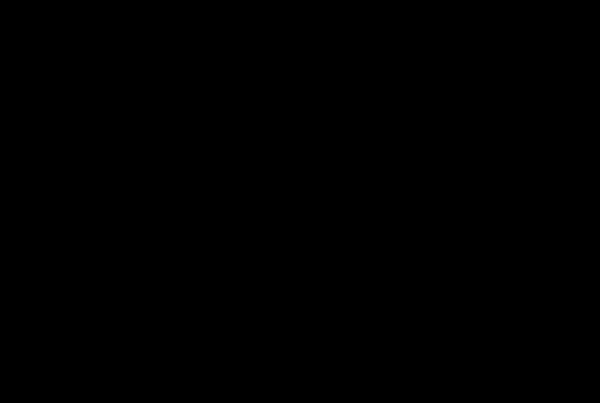

Navid Attarzadeh holding a prickly pear.

Zoe Kurland / Marfa Public Radio

But platinum’s not the only metal they can use for electrolysis, so these scientists have been looking for a cheaper alternative, like nickel. For nickel to work, however, it has to be transformed. That’s a difficult process. And the structure of the prickly pear cactus helped them figure it out.

Whereas previous designs had used one kind of nickel, this one contains two kinds of nickel fused together in the shape of the cactus leaf and fruit. The leaf is made of nickel phosphide, and the fruit is made of nickel sulfide.

This design allowed for more surface area, which was a boon for the lab. “We could enhance electron mobility with that prickly pear cactus structure,” Attarzadeh explained.

And it worked. More electron mobility meant more electrochemical reactions, which in turn created more hydrogen.

While nickel still isn’t as efficient as platinum, it makes up for that in cost. Platinum is more than 1,000 times as expensive as nickel.

As Brian Korgel, professor of chemical engineering at the University of Texas at Austin, tells it, this isn’t the first time nature has inspired a greener solution to an energy problem. This field of research is called biomimetics.

“It’s a made-up word, ‘biomimetic,’” Korgel said. “I don’t know who made it up, but it basically means bio-mimicking or bio-inspired.”

Korgel said biomimetics has generated many fascinating innovations: color-changing paint inspired by butterflies, a robot that moves like an octopus, artificial bones and more.

Plants have long inspired how we develop the materials that speed up chemical reactions, Korgel noted.

He said biomimetics is especially useful for hydrogen research. “We’re looking at these are the things nature’s figured out over time, and how can we adopt those to make hydrogen more efficiently?”

This is the principle behind the University of Texas at El Paso’s design. But even with promising results, how realistic is it for this new process to leave the lab and be used more widely? Chintalapalle said the cactus design worked at the lab level, but it has to be scaled up.

Navid Attarzadeh, left, and Ramana Chintalapalle in the Center for Advanced Materials Research lab.

Zoe Kurland / Marfa Public Radio

“We don’t know much about the mass production,” Chintalapalle said. “What are the difficulties? What are the challenges?”

Texas already has a lot of hydrogen infrastructure due to the state’s booming oil and gas industry — pipelines for transport and facilities to store the gas. But a new electrolysis process would require creating a supply chain from scratch, so it could be decades before we see the fruits of this cactus-inspired design.

However, when the time comes, if there’s any place poised to create a flourishing hydrogen industry, it’s Texas.